TEMPERATURE CONTROL - TEMPERATURE CONTROL -

An important starting note …. Temperature control should be used to give the adhesive a workable range of open time and shape stability. It should not be a function of controlling the dispense rate of the adhesive. If the dispense rate fluctuates due to temperature, change the drive system to eliminate fluctuations.

In the year 2010 we got some rude awakenings about what is required to temperature control dispense applications in radical ambient temperatures. It has cost us some money and is a lesson well learned. While there are needs for companies to reflect on actual process temperatures in their facilities, it is still our obligation to meet their needs when possible. From this lesson, we have developed “water jacketed” dispense hoses which scrub a significant amount of BTUs off the process and better allow us to control temperatures. This coupled with water traced lines for final segments allow us to fine tune temperatures where they are needed for processes. We have also increased chiller sizes to meet the needs of these applications.

On processes which require temperature “conditioning” of adhesives/sealants, we offer our original temperature control systems. (120vac@13fla) These temperature control systems (heat/cool system) were chosen for dependability and simplicity. We modify the pumping system to allow higher output pressures to drive coolant through a longer length of tubing. On processes which require temperature “conditioning” of adhesives/sealants, we offer our original temperature control systems. (120vac@13fla) These temperature control systems (heat/cool system) were chosen for dependability and simplicity. We modify the pumping system to allow higher output pressures to drive coolant through a longer length of tubing.

We chose a heat/cool system because applications we sometimes see have a summer and winter ambient temperature swings. These units will maintain a system temperature within a 5-10 degree F window. This window allows for a stable open time for adhesives and prevents viscosity swings do to seasonal temperature changes. They periodically need seasonal setpoint adjustments.

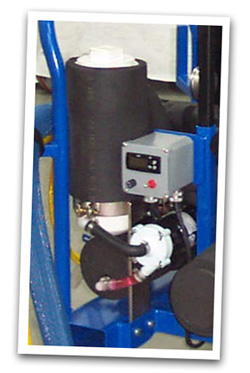

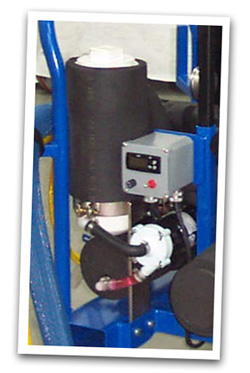

The customer’s dispense rate will determine water tracing requirements. A system with a low output may only need water traced dispense hoses. A high output system may require tracing of reservoirs drums, heat exchangers, and water jacketed dispense hoses. All temperature controlled components are insulated for the best results.

For tighter control of temperatures due to short open time adhesive, or higher ambient temperatures, we offer larger chillers with higher pressure circulating pumps. Water traced or coil cooled reservoirs are used as well as water jacketed hoses (and some water traced) as well as thicker insulation. A thermocouple is also recommended to give a constant readout of one or both sides of the adhesive close to the dispense point. The thermocouple may also be used to control the water valves to bring the adhesive temperatures to a tight tolerance.

These “higher output” systems increase the costs of a project significantly, but are sometimes necessary for the process. While the smaller chillers in a less critical process cost in the range of $4500 to 5500, the higher output systems can start at $7500 and range to $12,000 depending on the requirements. Voltage requirements will also come into play and create cost adjustments. |

TEMPERATURE CONTROL -

TEMPERATURE CONTROL -  On processes which require temperature “conditioning” of adhesives/sealants, we offer our original temperature control systems. (120vac@13fla) These temperature control systems (heat/cool system) were chosen for dependability and simplicity. We modify the pumping system to allow higher output pressures to drive coolant through a longer length of tubing.

On processes which require temperature “conditioning” of adhesives/sealants, we offer our original temperature control systems. (120vac@13fla) These temperature control systems (heat/cool system) were chosen for dependability and simplicity. We modify the pumping system to allow higher output pressures to drive coolant through a longer length of tubing.